The warehousing industry has undergone a lot of changes in recent years. Perhaps the most significant change has been the introduction of new technology. In the past, warehouses were largely reliant on manual labour to get the job done. But today, they are increasingly using robots and other forms of automation to improve efficiency and productivity. This is particularly evident in the way that warehouses are using conveyor systems to move goods around. In the past, these systems were operated manually, but today they are often automated.

Another change that has taken place in the warehousing industry is the introduction of new storage methods. In the past, warehouses would typically use pallets to store goods. But today, they are increasingly using shelves and racks to store goods. This is because these methods of storage are more space-efficient and can be more easily accessed by robots and other automated systems.

The final key change that we will mention is the way that warehouses are using data. In the past, data was used primarily for inventory purposes. But today, data is increasingly being used to track the movements of goods within a warehouse. This information can be used to improve the efficiency of warehouse operations.

Here’s a deeper look into how technology has changed the warehousing industry.

1. Warehouse management systems

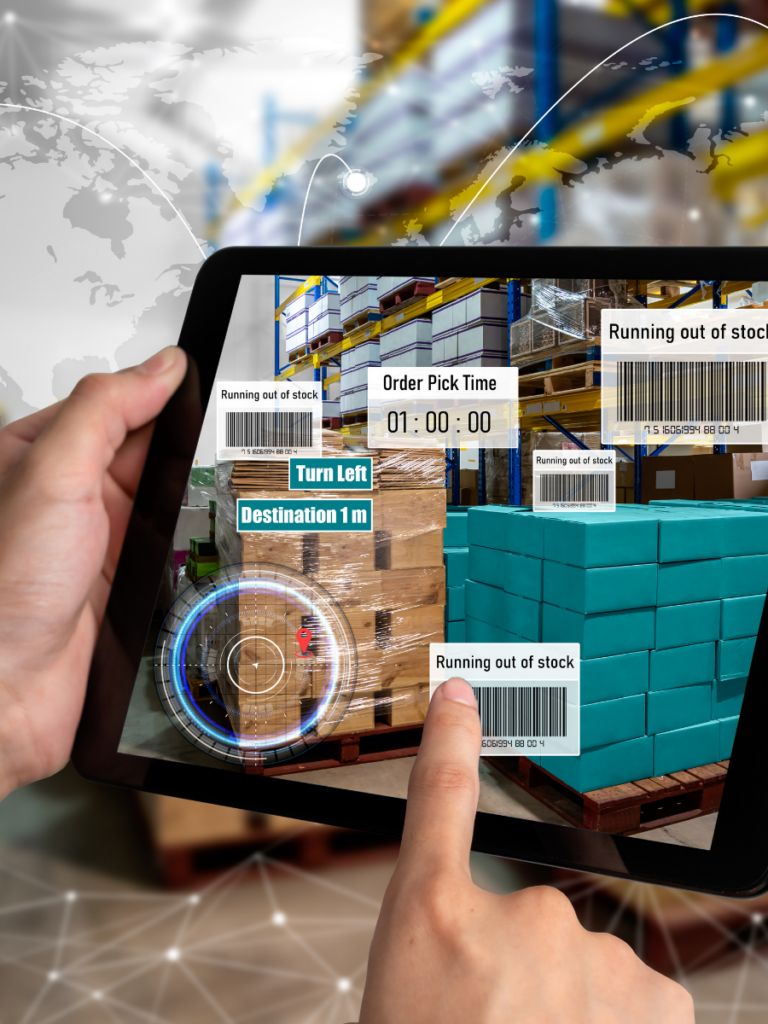

In the past, warehouses were managed using paper-based systems. This made it difficult to keep track of inventory levels and properly utilise storage space. However, warehouse management systems (WMS) have greatly improved the situation by automating many of the tasks associated with managing a warehouse. These systems use barcodes, sensors, and other forms of tracking to keep accurate and up-to-date records of what is happening in the warehouse at all times. This information can then be used to optimise various aspects of warehouse operations.

2. Radio-frequency identification (RFID)

RFID technology employs radio waves to communicate information between devices. RFID tags are often used to track inventory, and they can be very helpful in preventing losses due to theft or misplacement. Additionally, RFID tags can provide real-time information about the location of goods within a warehouse. This is particularly useful for picking operations, as it can help to ensure that the correct items are being picked and that they are being delivered to the right location.

3. Conveyor systems

Conveyor systems are used in warehouses to move goods from one point to another. In the past, these systems were operated manually, but today they are often automated. This helps to improve the efficiency of warehouse operations and reduces the amount of time that is required to move goods around. Additionally, automated conveyor systems can be integrated with other warehouse systems, such as WMS, to further improve efficiency.

4. Storage methods

As we mentioned earlier, the way that warehouses store goods have changed in recent years. In the past, warehouses would typically use pallets to store goods. But today, they are increasingly using shelves and racks to store goods. This is because these methods of storage are more space-efficient and can be more easily accessed by robots and other automated systems.

5. Data tracking

As we mentioned before, data is increasingly being used to track the movements of goods within a warehouse. This information can be used to improve the efficiency of warehouse operations. Additionally, data tracking can help to identify patterns and trends that can be used to further improve efficiency. For example, if it is discovered that a particular type of product is often misplaced, steps can be taken to correct the problem.

6. Forklifts and other material handling equipment

Another area where technology has made a big impact is in the realm of material handling equipment. In particular, forklifts have become much more advanced in recent years. Today’s forklifts are equipped with GPS, onboard computers, and other features that allow them to be operated more efficiently than ever before. Additionally, there are now many different types of forklifts available that can be adapted to specific needs. For example, there are now electric forklifts that emit no emissions, making them well-suited for indoor use.

7. Robotics

One of the most exciting recent advancements in warehouse technology is the introduction of robots. These robots can perform various tasks such as picking items off shelves and loading them onto delivery vehicles. Some warehouses are even using robotics to automate their entire order picking process from start to finish. While robots are still quite expensive, their costs are expected to come down over time as they become more widely adopted.

Technology has had a major impact on the warehousing industry over the last few years, and we will likely see even more advancements in warehouse technology in the years to come. As warehouses become increasingly automated, they will become more efficient and better able to meet the needs of their customers.

Warehouse management systems, forklifts, and robots are just some of the ways that technology is being used to improve efficiency and productivity in warehouses around the world. As these technologies become more commonplace, we’ll likely see even more changes in the way that warehouses operate in the future.